rockwell hardness test plain carbon steel hra|rockwell hardness chart : service In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors . Fica a par de toda a programação do Sport Lisboa e Benfica e dos jogos de futebol e outras modalidades que terão transmissão em direto e exclusivo na BTV. ter 27. .

{plog:ftitle_list}

WEB5 dias atrás · 29/02/24 - 20:45. Sporting - Benfica. Portugal Cup - Estadio Jose Alvalade. 2° Turno. Onde ver o jogo do Benfica hoje em direto. O jogo Sporting vs Benfica terá .

A, B and C in HRA, HRB and HRC in Rockwell hardness are three different standards, called scale A, scale B and scale C. Rockwell hardness test is one of several common indentation hardness tests used today. The initial pressure of the three scales is 98 07N (10 kgf), and finally calculate the . See more

iphone x vs samsung s10 drop test

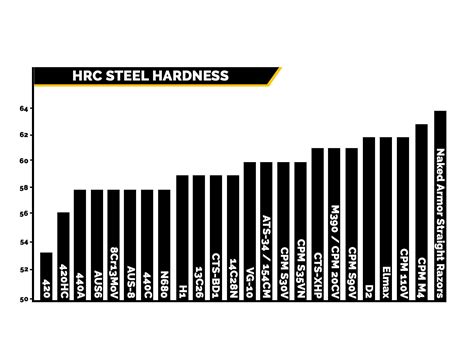

In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .Modern steels of powder metallurgy rank highest on the Rockwell scale and boast hardness around 64 and 68 HRC. These steels are rare (and hence, more expensive) and harder to process, but, when used correctly, they ensure . Rockwell hardness is expressed in three scales: HRA: Uses a 60kg load and a diamond cone indenter, suitable for extremely hard materials like hard alloys. HRB: Uses a 100kg load and a 1.58mm diameter hardened steel .

There are three methods for measuring Rockwell hardness: 1) HRA, using an indenter with diamonds, the measured value of the load is 60 kg; 2) HRC, the measured value . The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a .Rockwell Hardness Sensitivity Coefficients HRA. ISO 6508-1 defines the Rockwell A hardness value, HRA, as: h. HRA = 100 −. 2. where: = permanent depth of indentation under preliminary .

The Rockwell hardness test is widely used in various industrial applications, such as manufacturing, engineering, and quality control. It provides a quick and reliable measure of .

Rockwell Hardness Test. The Rockwell hardness test is based on the indentation depth caused by a diamond or a ball indenter under different loads. There are two main scales used in the Rockwell test: the Rockwell HRC scale .

The Rockwell Hardness Test presses a steel or diamond hemisphere-conical penetrator against a test specimen and measures the resulting indentation depth as a gage of the specimen .

Hardness testing blocks, made of carbon steel are used to calibrate metal hardness testers and come in various standard nominal values, such as 25 HRC, 45 HRC, 65 HRC, 90 HRB, and 83 HRA. . (83±3 HRA) Rockwell Hardness .The Rockwell hardness test is less affected by surface rough- . 60 kg HRA HRFW HRHW HRLW HRRW 45 kg (Superficial) HR45N HR45TW HR45WW HR45XW HR45YW 30 kg (Superficial) HR30N HR30TW HR30WW HR30XW HR30YW . including low-carbon steels, aluminum, lead, copper, and some plastics. The use of a large indenterASTM ASE AISI 1020 steel also known as C1020 steel in cold rolled condition. 1020 carbon steel properties, composition, yield strength, equivalent, density. . condition. 1020 carbon steel is one of the most commonly used plain carbon steels, has good machinability and weldability. . Hardness (HB) G10200: SAE 1020 steel: 1205 (175) 850 (123 .

Rockwell Hardness. Rockwell hardness test is widely used for a variety of materials. The diamond cone indenter is used to lightly press the surface of the material, and the depth of the indentation is measured to obtain the hardness. . and the depth of the indentation is measured to obtain the hardness. There are HRA, HRB, HRC and other . Rockwell hardness (HRC) = BHN/10-3 hardness measurement range: HS<100HB<500HRC<70HV<1300(80~88)HRA, (85~95) HRB, (20~70 )HRC In Rockwell hardness, A, B, C in HRA, HRB, HRC, etc. are three different standards, called scale A, scale B, and scale C. Rockwell hardness test is one of several common indentation hardness tests .

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.Reference Table: Steel hardness conversion chart - all values approximate. Brinell Hardness HB Rockwell HRC Rockwell HRB Vickers HV N/mm²; 800: 72---780: 71International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale.Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

Carbon steels are a category of steels with 0.12 to 2% carbon content. AISI 1045 is a medium carbon steel designed to be able to function in areas requiring greater strength and hardness. . Hardness, Rockwell B (converted from Brinell hardness) 84: 84: Hardness, Vickers (converted from Brinell hardness) 170: 170: Thermal Properties .

The austenitizing temperature for SAE 1045 induction hardening carbon steel is 800-845 °C. Full Annealing. The annealing temperature for AISI 1045 carbon steel is from 790-870 °C, cooling cycle from 790 to 650 °C at a rate of 28 °C/h in furnace, and can get the HBW hardness range from 156 to 217.

rockwell steel hardness

HRA : The Rockwell Hardness Test presses a steel or diamond hemisphere-conical penetrator against a test specimen and measures the resulting indentation depth as a gage of the specimen hardness. The harder the material, the higher the HR reading. . such as annealed carbon steels. C: Brale indenter 150 kgf load: Materials harder than HRB 100 . HV, HB, HRC Hardness Comparison Chart. Hardness testing is the simplest and most straightforward method among mechanical property tests. In order to replace certain mechanical property tests with hardness tests, a relatively accurate conversion relationship between hardness and strength is needed in production.. Experience has shown that there is .Hardness Testing Hardness testing can best be described as a measurement of “resistance to penetration” to a defined load. Several types or methods of hardness testing are more common and found in this table. . Carbon Steel Angle; Stainless Steel Angle 304/304L; Channel Shop By Shape Channel. All Channel Products . The Rockwell test is .

Reference Table: Steel hardness conversion chart - all values approximate. Brinell Hardness HB Rockwell HRC Rockwell HRB Vickers HV N/mm² : 800: 72 : 780: 71 : 760: 70 No, HRC is a specific scale within the Rockwell hardness testing method. Rockwell hardness testing includes several scales (e.g., Rockwell A, B, C), and HRC refers to the Rockwell C scale, which uses a diamond indenter. What does HRC 60 mean? HRC 60 means that a material has been tested and found to have a hardness of 60 on the Rockwell .Medium-carbon steel balances ductility and strength and has good wear resistance. For high-carbon steel hardness is higher than the other grades but ductility decreases. . a 1040 steel is a plain carbon steel containing 0.40 .Rockwell hardness test according to the material hardness, thickness of the test, can choose A different head and test, and the different scale, says the most common have A, B, C scale, in the . C Scale:Used for the determination of carbon steel, tool steel and alloy steel after heat treatment of steel products, such as the hardness of .

Brinell hardness of low-carbon steel is approximately 120 MPa. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. . Plain carbon steels are iron-carbon alloys in which the properties are primarily derived from the presence of carbon. Some incidental elements like .

Steels containing carbon as the major alloying element are called carbon steels. They may also contain up to 1.2% manganese and 0.4% silicon. Residual elements such as copper, molybdenum, aluminium, chromium and nickel are also present in these steels. AISI 1065 carbon steel is a high-carbon steel, which has high tensile strength and heat . Vickers Hardness; Rockwell Hardness; A plain carbon steel and an alloy steel were assessed using the Jominy end quench test. The hardness of the samples was measured as a function of the distance from the quenched end to demonstrate the different hardenability of the two steels. The data is shown as Vickers and Rockwell hardness.

Carbon amount up to 4.5% can be found in plain carbon steels, . Based on the results of rockwell hardness testing that the highest hardness value was achieved at 54.5 HRC in samples that have . In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.

MPa HV10 HB 1) HRB HRF HRC HRA HRD HR15N HR30N HR45N 255 80 76,0 – – – – – – – – . Vickers, Brinell and Rockwell hardness as well as tensile strength in steel and cast steel Table A.1 . hardness testing methods, but are practically used as . Rockwell hardness (HRC)=Brinell hardness (BHN)/10-3 hardness measurement range: HS<100HB<500HRC<70HV<1300 (80~88) HRA, (85~95) HRB, (20~70) HRC Rockwell hardness in HRA, HRB, HRC, etc. A, B, C are three different standards, called scale A, scale B, and scale C. Rockwell hardness test is one of several common indentation hardness tests .

Hardness testing blocks are designed for metals hardness testers calibration. There are available different standard nominal values of the blocks, such as: 25 HRC, 45 HRC, 65 HRC, 90 HRB, 83 HRA. Basically, the blocks are made from Carbon Steel, but also available blocks are made from Brass and Aluminium.It is usually used as carburized steel. Since most of the 1018 carbon steel is produced by cold drawing, this cold rolled steel is called C1018 (1018 cold rolled steel). AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and .

rockwell hardness vs hrb

Resultado da Privacy and Security Help Page. This page links to our help articles that answer privacy and security questions. We try to make information easy .

rockwell hardness test plain carbon steel hra|rockwell hardness chart